A basic welding machine is a device used to create a joint between two pieces of metal. It does so by generating an electric arc between an electrode and the workpiece, which melts the metals at the point of contact, allowing them to fuse together. Welding machines are widely used in various industries, such as automotive, construction, and aerospace, for joining metal components. Companies like Minoo Welding provide a range of welding machines suitable for different applications and skill levels.

Components of a Basic Welding Machine:

- Power Source: The power source is the heart of the welding machine. It converts the electrical energy from an outlet into a stable and suitable current for welding. The power source can be either AC (Alternating Current) or DC (Direct Current), depending on the type of welding machine and the welding process being used.

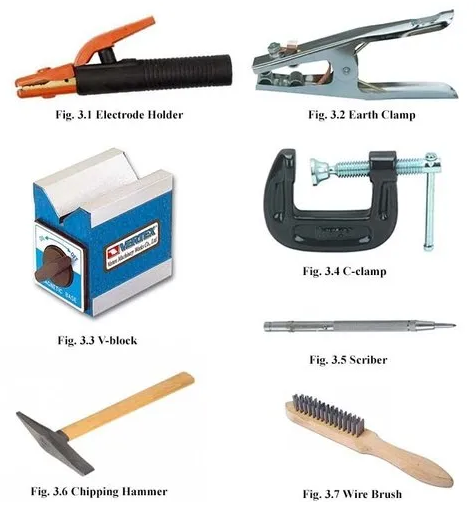

- Electrode Holder: The electrode holder is a clamping device used to hold the electrode securely during the welding process. It is connected to the power source via a cable and conducts the electric current to the electrode.

- Ground Clamp: The ground clamp is used to complete the electric circuit by connecting the workpiece to the power source. It is attached to the workpiece and connected to the power source via a cable.

- Electrode: The electrode is a conductor that carries the electric current from the welding machine to the workpiece. There are two types of electrodes: consumable and non-consumable. Consumable electrodes melt during the welding process to form the weld, while non-consumable electrodes do not melt.

- Welding Cable: The welding cable is a specially designed cable used to conduct the electric current from the power source to the electrode holder and ground clamp.

Types of Basic Welding Machines:

- Stick Welding Machines: Stick welding, or Shielded Metal Arc Welding (SMAW), is one of the oldest and most common welding processes. Stick welding machines use a consumable electrode coated with flux to lay the weld. The flux coating on the electrode melts during welding, creating a gas shield that protects the weld pool from atmospheric contamination.

- MIG Welding Machines: MIG (Metal Inert Gas) welding, or Gas Metal Arc Welding (GMAW), is a process that uses a continuously fed solid wire electrode and an inert gas to shield the weld pool from atmospheric contamination. MIG welding machines are popular because of their versatility and ease of use.

- TIG Welding Machines: TIG (Tungsten Inert Gas) welding, or Gas Tungsten Arc Welding (GTAW), is a process that uses a non-consumable tungsten electrode and an inert gas for shielding. TIG welding machines are known for producing high-quality, clean welds with minimal spatter.

- Flux-Cored Welding Machines: Flux-cored arc welding (FCAW) is a variation of MIG welding that uses a tubular wire filled with flux instead of a solid wire. Flux-cored welding machines are known for their high deposition rates and are suitable for welding thick materials.

Selecting the right welding machine depends on various factors such as the type of metal being welded, the thickness of the metal, the welding position, and the required weld quality. Companies like Minoo Welding offer a range of high-quality welding machines suitable for different applications and skill levels. High-quality equipment is essential for achieving strong and durable welds, ensuring safety, and increasing overall efficiency.